- EMAIL US:

info@standardforges.com

- CALL US:

+919555-558-183

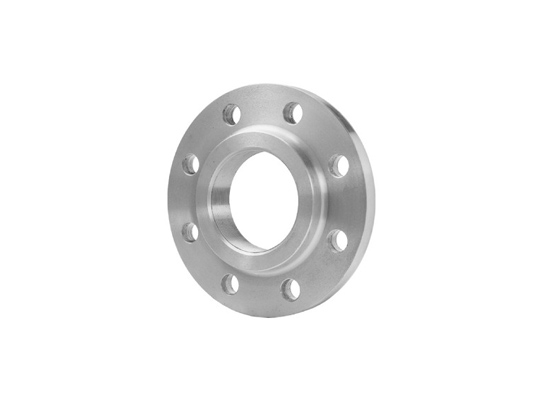

The Socket Weld Flange’s counter bore is slightly larger than the outer diameter of the matching pipe, allowing the pipe to be inserted into the flange similar to a slip-on flange. The diameter of the smaller bore is the same as the inner diameter of the matching pipe. A restriction is built into the bottom of the bore which sets as a shoulder for the pipe to rest on. This eliminates any restriction in flow when using a socket welding flange.

ANSI B 16.5, B 16.1, B 16.47 Series 'A' and 'B', MSS SP-44, JIS SK, 10K, 16K, DIN, BS

ASTM A-105, ASTM A-350 LF-2, A182 F-304/F-304H/F-304L/ F-316L/ F-321/ F-347/F-316Ti, A 181 F-1/F-5/F-11/F-22, ASTM A182 F-5/F-9/F-11/F-22, AISI 304/410/420/3042 or any other IS, DIN, JIS or international standards in Carbon/ Alloy/ Stainless Steel.

| Class | Size | Class | Size |

| 150 | 1/2" to 60" | 900 | 1/2" to 48" |

| 300 | 1/2" to 60" | 1500 | 1/2" to 36" |

| 600 | 1/2" to 48" | 2250 | 1/2" to 36" |

The Weld Neck Flange is normally referred to as the "high hub" flange. It is designed to transfer stresses to the pipe, thereby reducing high stress concentrations at the base of the flange. The welding neck flange is the best-designed butt-welded flange of those currently available because of its inherent structural value. It is expensive because of the design.

These are mainly used on heat coupling of pipes when there is possibility of expansion of the section while bending stress on the coupling.

ANSI B 16.5, B 16.1, B 16.47 Series 'A' and 'B', MSS SP-44, JIS SK, 10K, 16K, DIN, BS 4504

ASTM A-105, ASTM A-350 LF-2, A182 F-304/F-304H/F-304L/ F-316L/ F-321/ F-347/F-316Ti, A 181 F-1/F-5/F-11/F-22, ASTM A182 F-5/F-9/F-11/F-22, AISI 304/410/420/3042 or any other IS, DIN, JIS or international standards in Carbon/ Alloy/ Stainless Steel.

| Class | Size | Class | Size |

| 150 | 1/2" to 60" | 900 | 1/2" to 48" |

| 300 | 1/2" to 60" | 1500 | 1/2" to 36" |

| 600 | 1/2" to 48" | 2250 | 1/2" to 36" |

A Blind Flange is a solid disk used to block off a pipeline or to create a stop. The blind flange is machined in the same manner as a regular flange with the mounting holes around the perimeter and the gasket sealing rings machined into the mating surface. When a pipeline is being constructed, a blind flange is often incorporated into the final length of pipe. This design allows for expansion or continuation of the pipeline by simply adding onto the final flange. This holds true for the addition of tees in the pipeline as well. A tee can be installed and then blocked in order to leave the option of running a pipe at a later date.

ANSI B 16.5, B 16.1, B 16.47 Series 'A' and 'B', MSS SP-44, JIS SK, 10K, 16K, DIN, BS 4504

ASTM A-105, ASTM A-350 LF-2, A182 F-304/F-304H/F-304L/ F-316L/ F-321/ F-347/F-316Ti, A 181 F-1/F-5/F-11/F-22, ASTM A182 F-5/F-9/F-11/F-22, AISI 304/410/420/3042 or any other IS, DIN, JIS or international standards in Carbon/ Alloy/ Stainless Steel.

| Class | Size | Class | Size |

| 150 | 1/2" to 60" | 900 | 1/2" to 48" |

| 300 | 1/2" to 60" | 1500 | 1/2" to 36" |

| 600 | 1/2" to 48" | 2250 | 1/2" to 36" |

The Lap Joint Flange is practically identical to a slip-on flange except it has a radius at the intersection of the bore and flange race. This radius is necessary to have the flange accommodate a lap joint stub end. Normally, a lap joint flange and a lap joint stub end are mated together in an assembly system.

These are primarily used when quick assembly and disassembly of pipe line section is required under limited working pressure.

ANSI B 16.5, B 16.1, B 16.47 Series 'A' and 'B', MSS SP-44, JIS SK, 10K, 16K, DIN, BS 4504

ASTM A-105, ASTM A-350 LF-2, A182 F-304/F-304H/F-304L/ F-316L/ F-321/ F-347/F-316Ti, A 181 F-1/F-5/F-11/F-22, ASTM A182 F-5/F-9/F-11/F-22, AISI 304/410/420/3042 or any other IS, DIN, JIS or international standards in Carbon/ Alloy/ Stainless Steel.

| Class | Size | Class | Size |

| 150 | 1/2" to 60" | 900 | 1/2" to 48" |

| 300 | 1/2" to 60" | 1500 | 1/2" to 36" |

| 600 | 1/2" to 48" | 2250 | 1/2" to 36" |

A Blind Flange is a solid disk used to block off a pipeline or to create a stop. The blind flange is machined in the same manner as a regular flange with the mounting holes around the perimeter and the gasket sealing rings machined into the mating surface. The difference is that a blind flange has no opening to allow fluid to pass through. The blind flange can be inserted between two open flanges and used to block off the flow of liquid through a pipeline.

These are primarily used when quick assembly and disassembly of pipe line section is required under limited working pressure.

ANSI B 16.5, B 16.1, B 16.47 Series 'A' and 'B', MSS SP-44, JIS SK, 10K, 16K, DIN, BS 4504

ASTM A-105, ASTM A-350 LF-2, A182 F-304/F-304H/F-304L/ F-316L/ F-321/ F-347/F-316Ti, A 181 F-1/F-5/F-11/F-22, ASTM A182 F-5/F-9/F-11/F-22, AISI 304/410/420/3042 or any other IS, DIN, JIS or international standards in Carbon/ Alloy/ Stainless Steel.

| Class | Size | Class | Size |

| 150 | 1/2" to 60" | 900 | 1/2" to 48" |

| 300 | 1/2" to 60" | 1500 | 1/2" to 36" |

| 600 | 1/2" to 48" | 2250 | 1/2" to 36" |